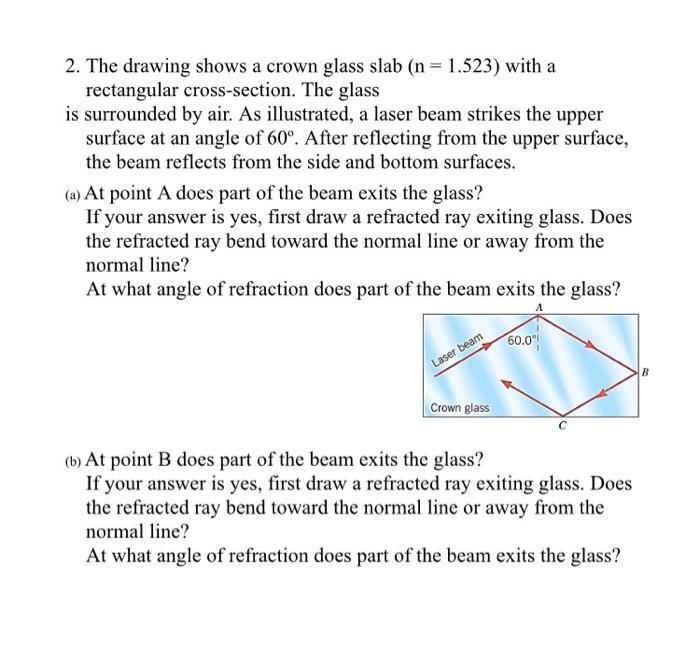

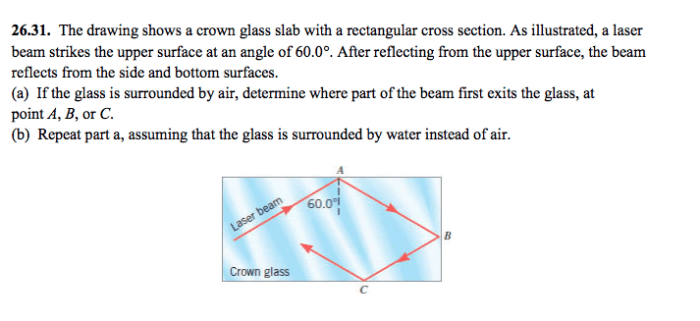

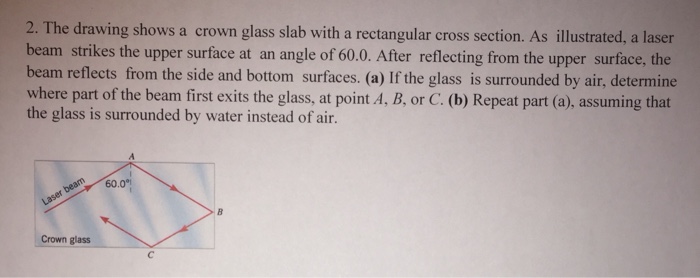

The drawing shows a crown glass slab – The drawing depicts a crown glass slab, an optical material with unique properties that have made it indispensable in various applications. This article delves into the intricacies of crown glass slabs, exploring their physical characteristics, manufacturing process, and diverse uses.

General Overview of Crown Glass Slabs

A crown glass slab is a flat, circular piece of glass produced by the crown glass blowing method. This technique involves gathering molten glass on the end of a blowpipe and swinging it in a circular motion, creating a centrifugal force that spreads the glass into a thin, flat disk.

Crown glass slabs have been used for centuries in various applications, including windows, mirrors, and lenses. They are prized for their clarity, low distortion, and smooth surface. However, due to the limitations of the hand-blown process, crown glass slabs are relatively small and have uneven thicknesses.

Historical Development

The earliest known crown glass slabs were produced in the Roman Empire around the 1st century AD. These early slabs were crude and small, but they gradually improved over time. By the Middle Ages, crown glass slabs were being produced in Europe, and they became the standard glazing material for windows.

In the 17th century, the invention of the cylinder glass blowing method led to the development of larger and more uniform crown glass slabs. This method involved blowing a cylinder of glass and then cutting it open and flattening it.

Cylinder glass slabs were used in the construction of large windows, such as those in the Palace of Versailles.

In the 19th century, the invention of the sheet glass blowing method led to the decline of crown glass slabs. Sheet glass slabs were larger, more uniform, and less expensive to produce than crown glass slabs. As a result, crown glass slabs are now rarely used, except for specialized applications.

2. Physical Properties

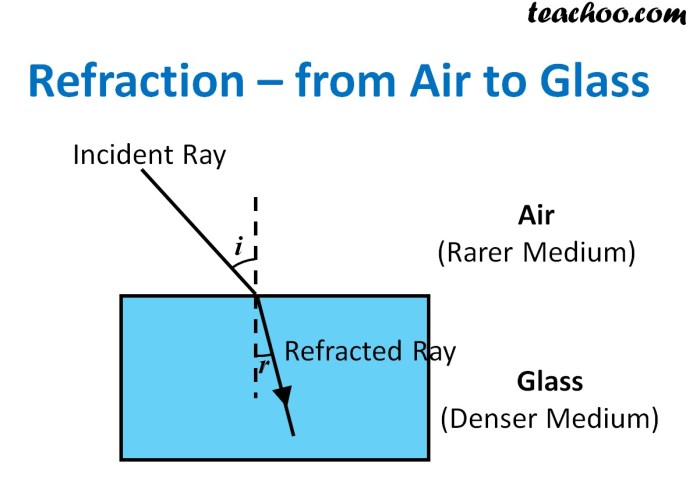

Crown glass slabs exhibit distinctive optical properties that make them highly suitable for various optical applications. These properties include refractive index, dispersion, and transmittance.

Refractive Index

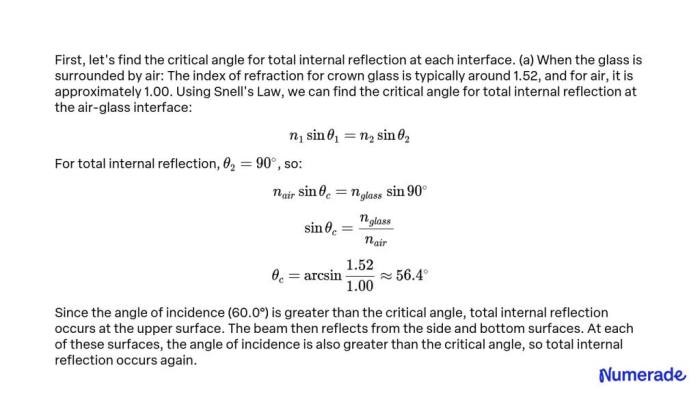

The refractive index of a material describes its ability to bend light as it passes through. Crown glass slabs typically have a refractive index in the range of 1.51 to 1.52, which is lower than that of other types of optical glass, such as flint glass.

This lower refractive index results in less bending of light when passing through crown glass, making it suitable for applications where minimal distortion is desired.

Dispersion

Dispersion refers to the variation in the refractive index of a material with wavelength. Crown glass slabs exhibit relatively low dispersion, meaning that they do not significantly spread out different wavelengths of light as they pass through. This low dispersion property is crucial for applications where it is essential to maintain the integrity of the light spectrum, such as in lenses and prisms.

Transmittance

Transmittance measures the ability of a material to allow light to pass through it without being absorbed or scattered. Crown glass slabs have high transmittance in the visible spectrum, allowing most of the light to pass through without significant loss.

This high transmittance makes crown glass suitable for applications where light transmission is paramount, such as in windows, mirrors, and optical lenses.

3. Manufacturing Process

The manufacturing process of crown glass slabs involves several intricate steps that require precision and expertise.

The primary raw material used in the production of crown glass slabs is molten glass, typically composed of silica, soda ash, and lime. The molten glass is carefully poured onto a flat surface, forming a circular pool.

Blowing and Shaping

A skilled glassblower uses a blowpipe to gather molten glass from the pool and shape it into a hollow sphere. The sphere is then reheated and expanded by blowing air into it, creating a thin-walled bubble.

Spinning and Flattening

The glass bubble is attached to a rotating spindle and spun rapidly. As it spins, centrifugal force causes the bubble to flatten into a circular disc. The disc is then reheated and annealed to relieve internal stresses.

Polishing and Finishing

The flattened glass disc undergoes a series of polishing and grinding processes to remove any imperfections and achieve the desired surface quality. The edges of the slab are trimmed to give it a rectangular shape, and the final product is inspected for clarity and optical distortions.

The manufacturing process significantly influences the quality and properties of the final crown glass slab. Proper temperature control, precise shaping, and meticulous polishing are essential for producing slabs with high optical clarity, low distortion, and excellent surface smoothness.

4. Applications

Crown glass slabs have a wide range of applications in optics due to their unique properties, such as high refractive index, low dispersion, and excellent optical clarity.

Lens Manufacturing

Crown glass slabs are commonly used for the production of lenses, including plano-convex, plano-concave, and biconvex lenses. The high refractive index of crown glass allows for the creation of lenses with shorter focal lengths, making them suitable for applications requiring high magnification or narrow field of view.

Prisms

Crown glass slabs are also used in the construction of prisms, which are optical elements that refract and disperse light. The low dispersion of crown glass ensures minimal distortion and chromatic aberration, making it ideal for applications in spectroscopy and color separation.

Windows and Viewports

Crown glass slabs are employed as windows and viewports in optical systems, such as lasers, microscopes, and telescopes. Their high optical clarity and low absorption allow for clear transmission of light, making them suitable for applications requiring precise optical alignment and minimal distortion.

Other Applications, The drawing shows a crown glass slab

In addition to the aforementioned applications, crown glass slabs are also used in various other optical components, including:

- Mirrors: As substrates for reflective coatings, providing a smooth and optically flat surface.

- Filters: As substrates for optical filters, blocking or transmitting specific wavelengths of light.

- Waveguides: As substrates for optical waveguides, guiding light through total internal reflection.

5. Advantages and Limitations

Crown glass slabs offer several advantages for optical applications:

- Excellent optical quality: Crown glass slabs have low levels of impurities and defects, resulting in high clarity and low distortion.

- Wide spectral range: They transmit light over a broad wavelength range, from the ultraviolet to the infrared.

- Chemical and thermal stability: Crown glass slabs are resistant to chemical corrosion and can withstand high temperatures, making them suitable for harsh environments.

- Cost-effective: Crown glass is relatively inexpensive compared to other optical materials, making it a viable option for large-scale applications.

However, crown glass slabs also have some limitations:

- Lower refractive index: Crown glass has a lower refractive index than some other optical materials, which can limit its use in applications requiring high magnification or beam steering.

- Higher dispersion: Crown glass exhibits higher dispersion than other optical materials, which can lead to chromatic aberration in imaging systems.

- Limited mechanical strength: Crown glass is relatively fragile and can be easily damaged by mechanical stress.

When choosing crown glass slabs for specific applications, it is essential to consider the trade-offs between its advantages and limitations. Crown glass is an excellent choice for applications requiring high optical quality, wide spectral range, and chemical and thermal stability.

However, it may not be suitable for applications requiring high refractive index, low dispersion, or high mechanical strength.

Question & Answer Hub: The Drawing Shows A Crown Glass Slab

What is the primary application of crown glass slabs?

Crown glass slabs are primarily used in optical applications, such as lenses, prisms, and windows, due to their high optical clarity and low dispersion.

How are crown glass slabs manufactured?

Crown glass slabs are manufactured through a process involving melting raw materials, shaping the molten glass, and then annealing and polishing the final product.

What are the advantages of using crown glass slabs?

Crown glass slabs offer advantages such as high optical clarity, low dispersion, ease of fabrication, and relatively low cost compared to other optical materials.