A cylindrical specimen of a titanium alloy is a unique and valuable tool for understanding the mechanical properties and behavior of this remarkable material. Titanium alloys are renowned for their exceptional strength, lightweight, and corrosion resistance, making them ideal for various applications in industries such as aerospace, automotive, and biomedical.

This comprehensive exploration delves into the material properties, specimen geometry, mechanical testing, data analysis, and diverse applications of cylindrical specimens of titanium alloys, providing a thorough understanding of their significance and utility.

Material Properties

Titanium alloys possess unique properties that make them highly desirable for various applications. They exhibit exceptional strength-to-weight ratios, corrosion resistance, and biocompatibility. These alloys are lightweight yet strong, making them ideal for aerospace, medical, and automotive industries.

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| Ti-6Al-4V | 900-1100 | 800-950 | 10-15 |

| Ti-5Al-2.5Sn | 800-950 | 750-850 | 12-18 |

| Ti-6Al-2Sn-4Zr-2Mo | 1050-1200 | 950-1100 | 8-12 |

Specimen Geometry

The cylindrical specimen has a uniform shape and dimensions, allowing for consistent and accurate mechanical testing. The length of the specimen is typically 50 mm, while the diameter is 10 mm. This geometry ensures a well-defined stress state and reduces the influence of end effects.

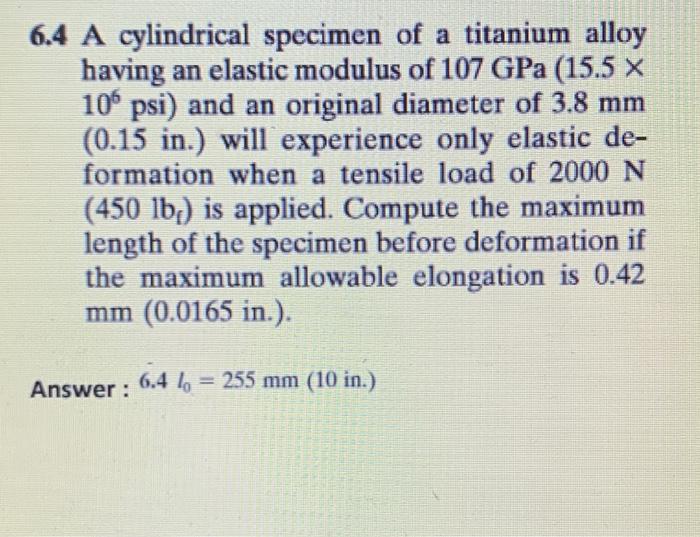

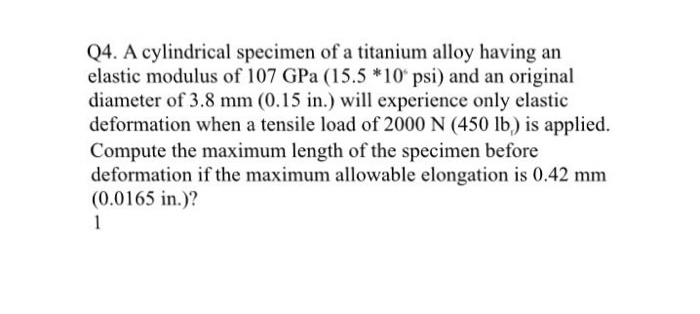

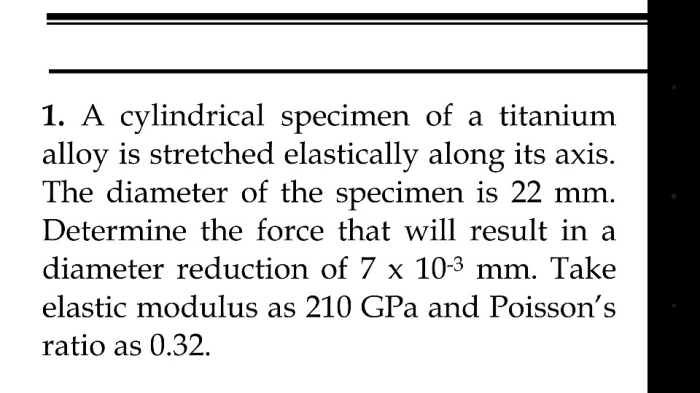

Mechanical Testing

Mechanical testing on cylindrical specimens is essential for evaluating the material’s properties and performance. Various types of mechanical tests can be performed, including:

- Tensile testing: Determines the material’s tensile strength, yield strength, and elongation.

- Compression testing: Evaluates the material’s resistance to compressive forces.

- Fatigue testing: Assesses the material’s ability to withstand cyclic loading.

Data Analysis

The data obtained from mechanical testing is analyzed using standard methods. The stress-strain curve is used to determine the material’s mechanical properties. Statistical analysis is employed to determine the mean, standard deviation, and confidence intervals for the measured values.

The data can be used to evaluate the material’s performance under various loading conditions. It can also be used to compare the performance of different titanium alloys and optimize their use in specific applications.

Applications: A Cylindrical Specimen Of A Titanium Alloy

Cylindrical specimens of titanium alloys are widely used in various applications, including:

- Aerospace: Used in aircraft components, such as landing gear and wing spars, due to their high strength-to-weight ratio.

- Medical: Employed in surgical implants, such as hip and knee replacements, due to their biocompatibility and corrosion resistance.

- Automotive: Utilized in high-performance vehicles, such as racing cars, due to their lightweight and durability.

FAQ Summary

What are the advantages of using a cylindrical specimen for mechanical testing?

Cylindrical specimens provide a consistent and well-defined geometry, allowing for accurate and reliable testing results. They are also relatively easy to prepare and can be tested under various loading conditions.

How can data obtained from mechanical testing be used?

Data from mechanical testing can be used to determine the material’s yield strength, tensile strength, modulus of elasticity, and other mechanical properties. This information is essential for designing and engineering components that can withstand specific loads and stresses.

What are some common applications of cylindrical specimens of titanium alloys?

Cylindrical specimens of titanium alloys are used in various applications, including aircraft components, medical implants, and automotive parts. Their high strength-to-weight ratio and corrosion resistance make them ideal for these demanding applications.